Coating

DM Powder Coating System

Published July 2, 2024

Extraordinary Trailer Finishes

While many trailer manufacturers choose powder coat and finish processes based solely on their material and operating costs, we designed this “Difference Maker” Powder Coating System to produce extraordinary trailer finishes.

The mantra is simple: Improve everything. Sacrifice nothing.

DM Powder Coating System Priorities:

– Adhesion

– Corrosion resistance

– Chip & abrasion resistance

– Gloss & color retention

– Curb appeal

We’ve spared no effort or expense to ensure that each Diamond C trailer comes with an extraordinary finish that is exceptionally durable and beautiful.

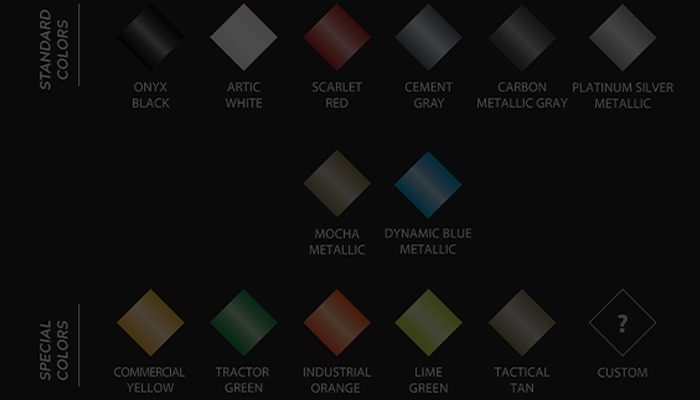

We’ve partnered with IFS to bring more enhanced color options, and are proud to offer multiple standard & special colors to choose from. View our comprehensive COLOR GUIDE to see all of our standard and custom colors up close.

COLOR GUIDEHow Does Powder Coat Work?

Listen in as Jacob walks you through the entire powder coat process, start to finish:

For a detailed in-depth guide and to see the entire powder coating facility up close, be sure to watch the following videos for a deep dive into all things DM Coating System, as well as a comprehensive conversation on the differences between custom, small-batch coating vs. industrial coating.

The Powder Coat Process

We use a 6-step process to ensure our custom trailer powder coating is the best coating option for your trailer:

Step 1:

Each trailer frame is blasted with steel shot to remove the mil-scale and add an anchor profile for the primer to adhere to.

Step 2:

Then we wash them with a 5-stage wash process to clean the steel, add corrosion resistance, and balance pH.

- Alkaline wash removes blast dust and oils

- High-pressure rinse

- Phosphate salt rinse inhibits rust and helps with paint adhesion

- High-pressure rinse

- Final sealing rinse is applied

All wash water is reverse osmosis (RO) purified to ensure consistency

Step 3:

Washed frames are promptly force-dried as they travel through our dry-off oven at 300 degrees. This prevents flash rusting and ensures that frames are primer-ready.

Step 4:

Ultra-corrosion-resistant Onecure Zinc Epoxy Primer powder coating is electrostatically applied to the entire trailer frame.

Step 5:

Smooth, high gloss, Onecure Technology Top Coat is electrostatically applied to the entire trailer frame.

Step 6:

The top coat is cured as the frame travels through our 165′ final-cure oven at 450 degrees. All steel surpasses 425 degrees to ensure complete curing of primer and top coat.

DM Powder Coat Differentiators

Pretreatment

Some powder coaters only blast. Some only wash. Others do a little of each. Every trailer that we powder coat is thoroughly blasted, washed clean, and chemically pretreated before powder application to ensure optimal surfaces for powder adhesion and corrosion resistance.

Powder

All powders are not created equally. We use IFS’s most advanced ultra-durable primer and top coat.

Hardware

Our powder line is highly engineered and 2400’ long with plenty of breathing room for thorough processing. Trailers flow through at a steady pace with no pushing or pulling required. It includes a number of pits and platforms throughout to enable operators to access trailers, over and under, comfortably and with ease which results in excellent coverage and consistency.

Purity

We use an extensive system of filters, separators, and refrigerated and desiccant air dryers to ensure that the compressed air we use for powder application is extremely pure, dry, and uncontaminated.

Control

All powder is applied in an environmentally controlled room for optimal application consistency. 60-80 degrees F.

Ovens

They’re convection ovens with several thousand points of airflow, electronically monitored and balanced, and have 18 million BTUs of natural gas-powered heat available to ensure consistent, complete powder curing.

Process

We audit the entire process, a multi-point inspection, every single day of operation to ensure that every machine, step, and process is performing consistently and optimally. Additionally, critical performance factors are monitored hourly at each booth to maintain tight controls and standards.

DM Powder Coat Downloads

View the attached flyer for a more in-depth look at our Powder Coat process.

DM COATING SYSTEM FLYER

Build Your Own Trailer

Every Diamond C trailer comes standard with our premium DM Powder Coating Systems finish. Click below to view and price all of our trailer models:

BUILD & PRICE